Rising Storage Risks: How Modern Warehousing Fuels Fire Hazards

PropertyArticleAugust 14, 2025

The growing popularity of a “too-tall, too dense” approach to commercial warehouse storage is increasing the size and severity of fires and with it, the risk to lives and property.

Warehouses by their nature are designed to support large-scale storage operations in a relatively small space. However, companies have been pursuing ways to increase the density of stock in the same amount of space. Factors contributing to this trend include the growing demands of e-commerce and just-in-time deliveries; automated technology that creates efficiencies for identification and retrieval of goods; and the desire to offset rising real estate costs by building up, not out.

Unfortunately, this trend is creating scenarios that set the stage for larger, more destructive fires that exceed the abilities of even the most experienced firefighters. Many modern warehouses are being constructed in rural areas, where nearby fire departments may lack sufficient personnel and resources to respond effectively.

To demonstrate the size and impact of fires in today’s commercial warehouses, consider these recent examples:

- A March 2024 warehouse fire near Detroit in Clinton Township, MI, resulted in one death when a propane canister propelled by an explosion struck a 19-year-old man far from the event. Following the fire, investigators found canisters more than two miles from the site.1

- On March 15, 2022, a massive fire tore through a major national retailer’s 1.2 million square-foot fulfillment center in Plainfield, IN. The facility, equivalent to 20 football fields, was a relatively new building protected by state-of-the-art fire suppression systems. Despite these protections, the building and contents were a total loss.2

- A six-alarm fire in a 151,000-square foot distribution warehouse in York County, PA, in July 2024 resulted in the total loss of the facility. Unable to extinguish the blaze fueled by combustibles stored inside, firefighters redirected efforts to protect surrounding buildings.3

- A massive fire in a West Baltimore, MD, mattress warehouse in May 2025 engaged more than 200 firefighters in a battle that disrupted Amtrak service and prompted officials to move dozens of area residents. The next day, rail service was canceled over fears of a building collapse onto the tracks.4

- A large warehouse fire in December 2024 in Commerce, CA, near Los Angeles resulted in the total loss of the facility, sending plumes of toxic smoke billowing throughout the area.5

For some perspective on the frequency of warehouse fires, consider data from the National Fire Protection Association (NFPA) reporting that local fire departments responded to an estimated annual average of 1,470 structure fires at warehouse properties in the U.S. during the five-year period from 2019 to 2022. These fires caused an estimated average of 3 civilian deaths, 19 civilian injuries, and $323 million in direct property damage.6

Clearly, the frequency and severity of warehouse fires underscores the need to address this risk. They pose life-and-death dangers to both the building occupants and firefighters, can result in millions of dollars of losses, and can adversely impact the local environment due to toxic smoke and chemical runoff. What’s more, inflation can further escalate the replacement costs of goods and the buildings that store them.

Storage configurations and technology create new challenges

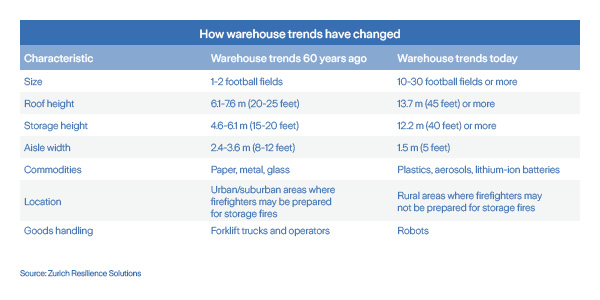

Consider how warehouse trends have changed over the past six decades:

1. Storage-savvy tech and sprinklers

In the past, warehouses handled goods by the pallet load and stored them in conventional piled or racked configurations. Over the past 50 years, sprinkler guidelines were developed for these conventional configurations and are found today in standards such as NFPA 13, “Standard for the Installation of Sprinkler Systems.” As warehouses evolve into fast-paced e-commerce fulfillment centers, materials are now stored and retrieved in smaller quantities. These new storage patterns can create fire risks that existing codes like NFPA 13 may not fully anticipate.

For example, the protection of racked storage depends on adequately sized and spaced flues to allow a fire’s heat to flow vertically up to sprinklers and sprinkler discharge to flow downward dousing a fire. With palletized goods, adequate flues for the most part were automatic. But with pallets broken down into case goods or individual items, flue spaces tend to be too small, misaligned vertically, or even omitted. Blocking flues and restricting water access to storage racks significantly increases the risk of a catastrophic fire. In addition, multi-row rack configurations can add to the challenge of sprinkler effectiveness and complicate the task of final extinguishment.

As another example, e-commerce warehouses often store goods in open-top containers to facilitate order picking. Standards such as NFPA 13 offer no protection guidance where open-top containers are used. The challenge here is that open-top containers capture the sprinkler discharge that would otherwise flow downward toward a fire. The outcome is similar to inadequate flues.

In general, the modern e-commerce warehouse needs sprinkler protection beyond NFPA 13 to be considered adequately protected.

2. Storage-savvy tech and firefighting

The pace of play in the e-commerce warehouse is driven by order fulfillment rates, especially where next-day delivery is offered. This drives a need for automatic storage and retrieval systems (ASRS), especially those using robots.

Traditional ASRS warehouses have always been a firefighting challenge. With goods stored 40 or more feet above the floor, firefighters have no realistic means to access fire-damaged goods in the upper storage tiers. Storage configurations may be in excess of 200 feet from the entrance point of the building, creating further challenges for responding personnel to access the area in full protective clothing and self-contained breathing apparatus (SCBA). Such SCBA equipment should be capacity-rated from 30-60 minutes, but practical operating times should be restricted to 15-30 minutes.

Also, newer robotic ASRS adversely impact firefighter access. Aisles are becoming too narrow or are even being eliminated. Narrow aisles hamper firefighters’ movements when they’re wearing personal protective gear that includes self-contained breathing apparatus. Firefighters may not even be able to turn around in an aisle! And, where aisles are eliminated, firefighters may have to work hours to access fire damaged goods located just 10 or 15 feet from an access point. Many of the robots are powered by lithium-ion batteries which can serve as an ignition sources.

In addition, lithium-ion batteries in countless consumer and industrial products warehoused in distribution centers represent a growing concern. Valued at over $44 billion in 2020, the global lithium-ion battery market is projected to reach $138 billion by 2026.7 This will mean a dramatic rise in the number of lithium-ion batteries installed in industrial and consumer products stored in warehouses and distribution centers.

While highly efficient power storage devices, lithium-ion batteries can be the source of fires in cases of manufacturing defects, mishandling or improper storage. Internal chemical reactions can result in a phenomenon called “thermal runaway,” prompting the battery to heat at a much faster and higher rate than during normal recharging and everyday use. Such thermal runaways can result in fire, explosion and the release of toxic gases.8

Access and Planning Are Critical for Warehouse Safety

Although storage trends are changing, the principles of fully extinguishing a fire still rely on two steps:

- Automatic Sprinkler Systems: These are designed to control or suppress a fire in its early stages. The goal is to prevent the fire from spreading and to keep it manageable until firefighters arrive. The design of these systems must be appropriate for the type of storage (e.g., height, materials, packaging) and follow standards like those from NFPA 13.

- Firefighter Intervention: Once the fire is under control or suppressed by the sprinklers, firefighters complete the extinguishment. Their role will ensure the fire is fully out, preventing rekindling and addressing any residual hazards.

Step two is crucial. Although sprinkler systems can control or suppress fires, it is the role of firefighters to achieve and confirm final extinguishment. A warehouse fire is not considered fully extinguished until all fire-damaged goods are removed from the building. There’s a reason for that. Even a tiny ember can smolder for hours and reignite a fire, potentially destroying the building.

Effective removal of materials during a fire depends on firefighters' ability to access them. When goods are stored too high or packed too densely, reaching fire-affected areas can become extremely difficult—or even impossible.

Even if firefighters can reach the goods, consider that they will be wearing full protective clothing with a limited duration of breathing air supply, all while working in unknown spaces and dealing with poor visibility conditions. Most of the time they’re on their hands and knees, dragging a hose. After they’ve already crawled 100 feet or more into the building, now they’re faced with a ton of material they must remove. In short, each warehouse needs a realistic final fire extinguishment plan that stays within the physical limits of human firefighters.

Furthermore, no property is ever worth the loss of life. We never want a firefighter to be harmed protecting property.

When access is impeded, the fire department is often forced to use large hose streams to try and control the fire. One of these hoses can release 250 to 500 gallons of water a minute, and sometimes more, creating even greater water damage to goods.9

Understanding the Hidden and Costly Risks of Smoke Damage in Warehouse Fires

It’s impossible to discuss fire-related property risks without addressing the adverse and costly impact of smoke. Fire obliterates what it consumes, but it also produces smoke and soot that can travel far beyond the flames. Depending on what has been burned, different types of smoke will result, incurring expensive cleanup costs but also the possibility of rendering impacted materials worthless.

Some points about smoke damage:

- Smoke from a fire can travel throughout a building, often reaching the outer walls.

- Smoke particles are ionized and carry electrical charges, which means smoke and soot can short-circuit electronics and contaminate HVAC systems.

- Cleaning smoke deposits from building features is labor-intensive and costly, requiring skilled professionals. For example, cleaning roof-level bar joists may need to be done by hand with special equipment, as pressure washing could damage sensitive equipment, utilities, or stored goods.

- Smoke causes discoloration and lingering odors, and it can significantly damage inventory. Depending on the product or its packaging, some items may not be salvageable after smoke exposure.

Economic Trends and Supply Chain Pressures Amplify Warehouse Fire Losses

Current economic trends also exacerbate the total cost of these massive fires. While these factors come into play for any commercial warehouse fire, their losses are multiplied when a fire destroys a single, gigantic property filled with goods. Consider:

- The loss of so many goods in a large warehouse jeopardizes the supply chain for all companies relying on those products. It further worsens an already strained global supply chain and adds to today’s inflationary environment.

- To protect their brand and avoid liability, businesses are less willing to sell or salvage products with any level of smoke damage than they have been in the past. As a result, smoke damage to stock increases, and so do the associated costs. Even if the damage affects only packaging, companies find that repacking can be as costly as replacing the product itself. Once again, inflation makes replacing products more expensive.

Proactive Steps to Prevent Storage Fires and Strengthen Warehouse Safety

Businesses need to take every possible precaution to prevent a storage fire. As discussed here, that includes avoiding the shortcomings of too-tall, too-dense warehousing. The better option is to have several warehouses that are adequately spaced, with storage configurations most likely to remain within the capabilities of your local public fire service and their sprinkler protection designs and allow adequate aisles and flue spaces.

Here are some additional tips from Zurich Resilience Solutions:

- Support the local fire department in the development of their pre-incident fire plan. This can be with tours of responding personnel which are most likely different from the fire code inspection personnel involved in construction of the building. Fire code inspectors and firefighting operational staff will be interested in location of automatic storage retrieval systems, utilities, and personnel contact information. Offer the installation of additional door signage, floor markings, etc., to assist fire personnel. Like any mitigation plan, this process should be reviewed and updated as necessary, especially if site conditions change.

- Consider frequent site tours with emergency response personnel. If a multi-jurisdictional response is needed for your location, ensure neighboring fire departments are also included in the site tours. Offer to host response drills with pre-determined likely fire scenarios which will drive site familiarization and build a good rapport with responding agencies. Some local law enforcement or emergency medical service agencies may also wish to participate with fire department personnel. Most likely these agencies will be involved in a response should an incident occur.

- The result of the evaluation of the local fire department capabilities and the situation at the site may lead to the assumption that the final extinguishment of the storage is not feasible. In such cases, it may be appropriate to consider the use of internal fire barriers, firewalls and external space separation distances.

- To ensure the effectiveness of your facility’s fire protection strategy, consult with a qualified fire protection engineer or licensed sprinkler contractor. They will verify that the automatic sprinkler system is appropriately designed for the specific hazard classification present in your facility. Additionally, they will ensure the system can meet the water supply requirements for both automatic sprinkler activation and manual fire suppression efforts. Reach out to Zurich Resilience Solutions for guidance.

- Regularly inspect, test and maintain your storage warehouse’s automatic sprinkler system.

- Plan for manual firefighting as a critical component of final fire extinguishment. Engage your local fire department to review warehouse layouts and storage configurations, ensuring they are familiar with the commodities and potential hazards. Storage design should align with the fire service’s capabilities in terms of staffing, training, equipment, and reach. Ask: can responders realistically access fire-damaged goods at your highest or deepest storage points?

- Ensure that any robotic or automated stock handling systems will shut down automatically upon fire detection. This includes smoke detection, heat detection, and a sprinkler’s water-flow detection.

- Train your staff so they will know which sprinkler control valve when directed by the fire department. Include a sprinkler zone map at each riser to indicate the area protected by that system. And, whenever sprinklers are shut off, maintain a fire watch posted in the fire area and a valve watch posted at the shut sprinkler valve. The fire watch is to immediately notify the valve watch to open the sprinkler valve if there are signs of a rekindling fire. Are all control valves clearly labeled as to the area they serve? Is there an associated reference drawing of a sprinkler system zones posted in a location requested by the fire department?

- Identify sources of water for manual firefighting. The water demands for storage fires can be very high, so it’s important to review the availability of water and conduct regular flow tests to help assure you have sufficient capabilities. Consider asking fire department personnel where their primary water supply is located and if they have a means or desire to have a secondary supply. Discuss means to support the identification of water supply (marking of hydrants etc.) and seek to learn what emergency vehicle access is needed. Are additional access roads desired, is fire lane markings sufficient?

- Develop a plan so fire-damaged goods are never left unsupervised inside a building. This risk-mitigation step anticipates the very real risk of fire-damaged goods reigniting.

- The results of the storage fire protection and final extinguishment evaluation should be integrated into the site’s overall hazard analysis, including potential impacts on business operations. Develop a coordinated operations plan for final extinguishment, specifying who is responsible, how the removal of damaged stock will be conducted (including required equipment), and when it should occur. Conducting periodic drills to rehearse this plan is strongly recommended.

Learn more about Zurich’s Property solutions.

References

1. Romero, Dennis; Burke, Minyvonne; Broaddus, Adrienne; Smith, Patrick. “One person killed after huge fire ignites Michigan warehouse, raining debris ‘as far as a mile away,’ police say.” NBC News. 5 March 2024.

2. Wright, Lincoln. “Walmart fire at Plainfield fulfillment center: What we know about massive Indiana blaze.” Indianapolis Star. 21 March 2022.

3. Weaver, Jared. “York warehouse contained products that helped fuel massive 6-alarm fire, official say.” WHTM ABC Channel 27. 19 July 2024.bx

4. Associated Press. >“Over 200 firefighters battle massive warehouse fire in West Baltimore.” WBFF Fox Channel 5. 13 May 2025.

5. Conybeare, Will. “Massive L.A. County warehouse fire sends toxic smoke into the air.” KTLA Channel 5. 15 December 2024.

6. McGee, Tucker. “Warehouse Structure Fires Report.” National Fire Protection Association. 31 January 2025.

7. Linder, Jannick. “Lithium Battery Fire Statistics.” Gitnux. 29 April 2025.

8. What is Thermal Runaway? UL Research Institutes. 24 August 2021.

9. Rowett, Jr., Anthony. “From Hoselines to Hydrants: Understanding Water Supply.” Firehouse. 14 November 2017.